05 Camry 2.4L. ~ 250K hassle free miles. Runs on both propane and gasoline. This particular issue is not related to running on propane but hopefully I have your attention.

Issue: p304 misfire.

Troubleshooting:

1- Checked plugs. Everything seemed ok. Replaced and properly gaped plugs. No change.

2- Checked for vacuum leaks. Sprayed all vac lines with starting fluid. No leaks detected.

3- Ruled out bad fuel injector by running the car on propane. The propane system uses a separate fuel injector system for injecting the propane into the intake runners. The propane computer piggybacks on the OEM sensors and will cut out the signal to the gasoline injectors and instead fire the propane injectors.

4- Swapped coils. Still # 4 misfire. Later replaced coil. No resolution.

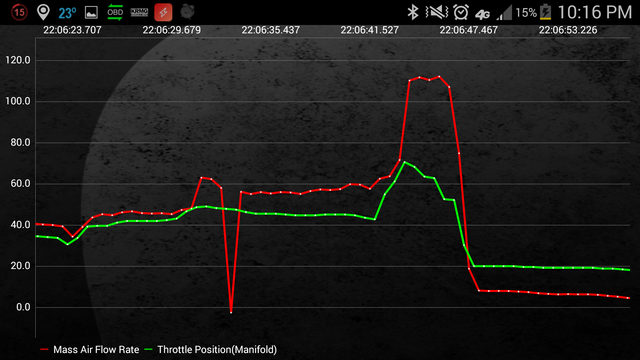

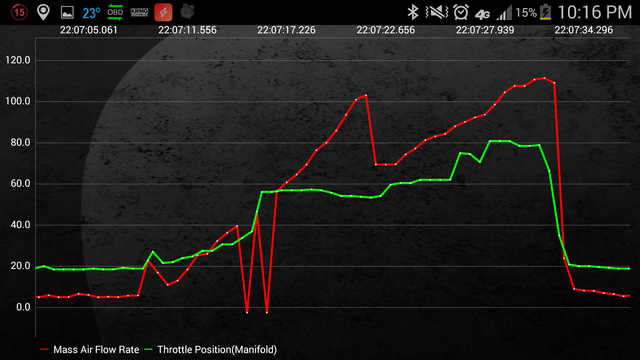

5- Downloaded Torque app and started monitoring engine sensors. Noticed that during acceleration the MAF would periodically lose signal. First cleaned MAF using the MAF cleaner and later replaced the MAF. No changes. See screenshot below.

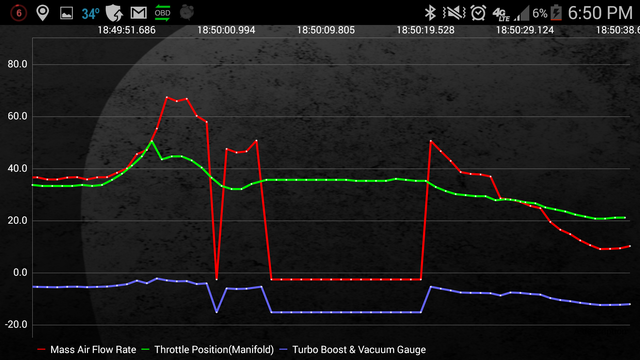

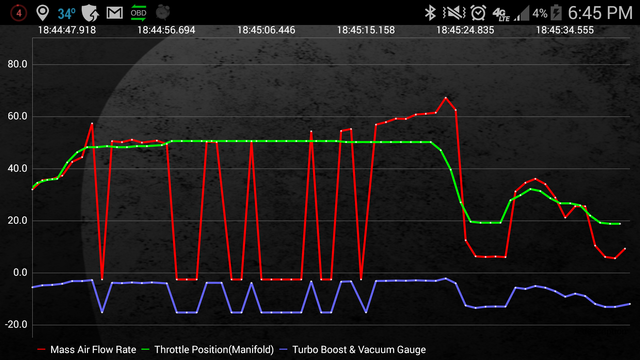

6- Continued to monitor the sensors and noticed that the MAF signal and vacuum signal would drop off. I later concluded that this appears to start happening ~ 2500 RPM. After some research, I noticed that the vacuum switching valve kicks in at 2500 RPM. I thought I had my answer. I replaced the switching valve (the one mounted on the air intake hose) with one at the salvage yard and I still have the same issue.

7- The manual i purchased does not have engine wiring diagram. It only has the stuff for power locks, windows, radio, etc. No sensor wiring diagrams. I need a detailed wiring diagram.

What are my other options? Need advise.

I have not checked the compression. I ruled this out when I noticed the sensor signal issues. I have always monitored the oil via oil analysis and never noticed any excessive wear metals in the oil.

I suspect there is a wiring issue on a wire that is running the vacuum switching valve or the MAP. Other potential issue is faulty computer.

Other maybe useful information but I doubt it. Car has 250K miles. Was converted to run on LPG @ 100K. Of the last 150K miles 90% of this has been on cheap and clean burning propane. For the past couple of years, I get a puff of smoke at startup. I have always assumed this was worn valve guides or valve seals. Likely guides since propane does not provide the same lube to the valves that ethanol lased gasoline provides. I typically change my oil at 15-20K mile increments and have sampled the oil and never detected any premature wear metals. When running on propane the oil is just as clean after 20K miles as it was when it was put in the engine. Maybe I will recycle this lightly used oil in my lawnmowers.

Other maybe useful information. I live deep in the sticks. I have had a problem with pack rats eating wires and hoses on my trucks that typically sit unused weeks at a time. People look at me strange when I use the vacuum at the car wash under my hood but not on the inside of the farm truck. Never had a issue in my cars maybe because the wires are not made with soy or fish oils like some wires are or maybe it is because the car is always parked at the house and my cat named Death Ray does a good job of exterminating anything that moves near the house. Here is the picture of the rat that I caught in one of my trucks.