The right pressure can be determined by knowing the tire manufacturers optimum tire footprint.

Once that is known and the weight of the vehicle you can calculate the correct tire pressure.

The right pressure can be determined by knowing the tire manufacturers optimum tire footprint.

Once that is known and the weight of the vehicle you can calculate the correct tire pressure.

And how would you know the ‘tire manufacturers optimum tire footprint’?

Not trying to be obtuse, but I can think of no way for somebody other than a tire maker or car manufacturer to get a better psi number.

but I can think of no way for somebody other than a tire maker or car manufacturer to get a better psi number.

That is correct.

Tire footprint is rarely used that way. Where it comes in handy is when you use the same tires on another vehicle that weighs differently. The more weight the higher the tire pressure will be.

Knowing the optimum footprint would be great, though I wonder if a little real world adjustment (upward) might be needed after the calculation.

Without more info, it seems the chalk test is reasonable for seeing if there is even weight distribution across the width of the tread. This seems necessary because overly high pressure means more wear in the center of the tread while low pressure means wearing out on the edges. These effects are seen even where the footprint looks very similar.

I suspect that after a chalk test, a bump up by 2-3 psi is a safe bet.

Sorry guys, but while I am far from an expert in tread patterns (I am more of a generalist), tires happens to be my area of expertise and while you may not believe it, the average contact pressure (ACP) is NOT equal to the inflation pressure. With passenger car tires, the ACP is close, but in trucks (as in the 18 wheel variety), it isn’t. Unfortunately, this was studied so far in the past and is of so little technical value, that there aren’t any direct studies available to read. What one finds is stuff imbedded in a paper on a another topic - and usually those papers are of interest to a tire engineer and no one else.

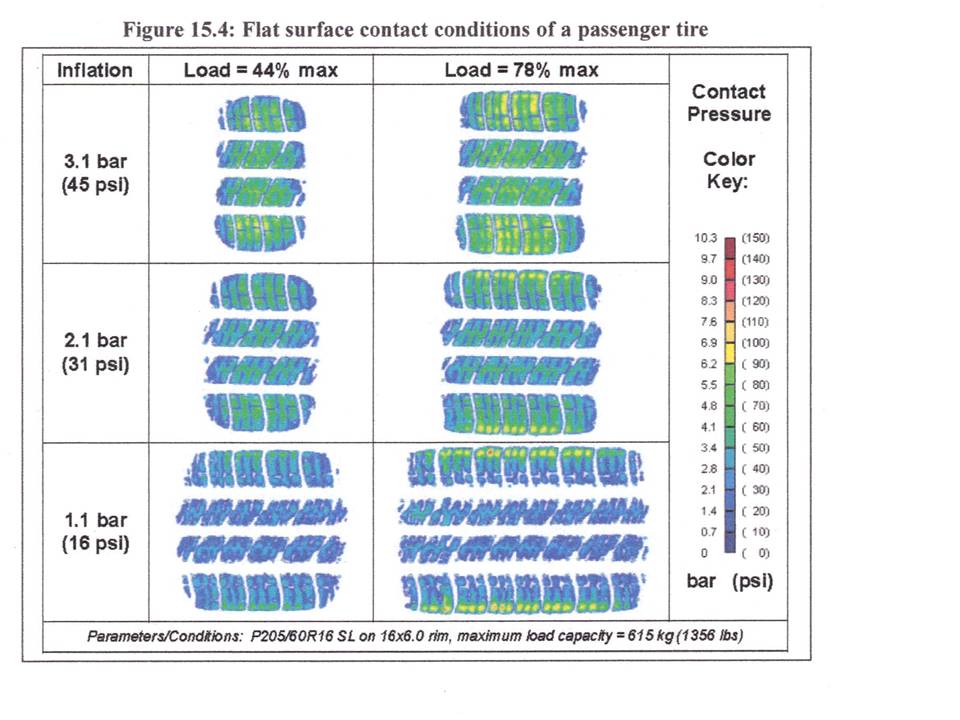

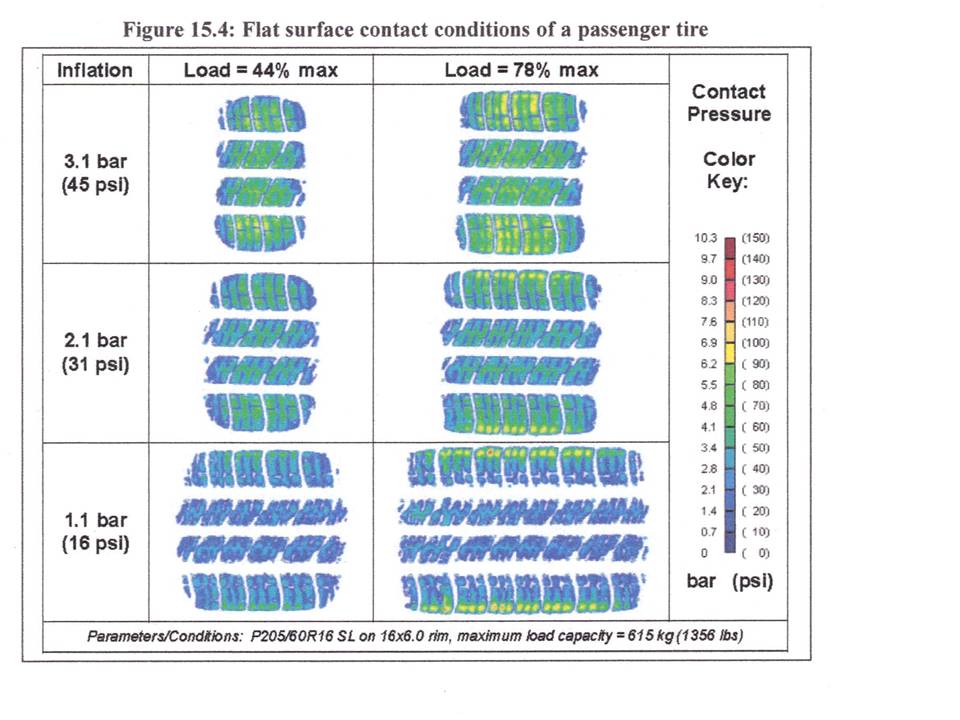

As proof I offer a study that I originally saw in 2009. Like I said, the information we are seeking is buried deep.

BTW, I do NOT expect anyone to be convinced who is not already convinced - but it hardly matters. This isn’t an earth-shattering kind of thing. At best, it is a bit of trivia. But I will leave everyone with this conundrum:

Consider a RunFlat tire operating with no inflation pressure. It’s footprint is only somewhat larger than it would be if fully inflated.

Waterbuff,

Tire engineers can alter the size and shape of a tire’s footprint - but a good tire engineer will attempt to optimize the contact shape and pressure distribution such that not only is it relatively unaffected by pressure and load, but such that it is close to optimal for normal loads and pressures.

To give you an idea, here’s one:

Notice that the width of each contact patch is about the same and what varies is the length. I think this says that “The Chalk Method” is not going to yield something useful in determining optimal inflation pressure.

Sorry guys, but while I am far from an expert in tread patterns (I am more of a generalist), tires happens to be my area of expertise and while you may not believe it, the average contact pressure (ACP) is NOT equal to the inflation pressure

Sorry Capri…but Math and Physics doesn’t change because you’re an expert on tires.

I don’t know anyone who said anything about contact pressure. Contact pressure will vary from tire to tire…based on elasticity of the tire. But…so what. You can still get a fairly accurate measurement of a vehicles weight by it’s footprint and tire pressure.

Taken directly for Physics text book.

CapriRacer, thanks very much for the .jpg picture with contact pressure footprints. I’m certainly not an expert, so to me the picture gives more info than what the chalk test approximates. The picture certainly shows a very noticeable effect of pressure on length of contact patch.

For width of the patch, there does seem to be pressure variations that match the common view that at a given load or weight, low tire pressure means more wear on edges. The effect of high pressure causing more wear on center of tread does not seem as apparent.

But as you’ve pointed out, tire engineers can alter how a tire responses to inflation pressure and load. My OP is based on the possibility that an OE tire might have the “recommended” footprint at the “recommended” pressure on the sticker while a newer non-OE tire, where the engineer might have changed things, might need a slightly higher pressure to perform the same way on the vehicle.

@CapriRacer - what do you think about the ‘chalk test’?

Texases said: “… What do you think about the ‘chalk test’?..”

Not a fan. I don’t think it does what it is reported to do - that is, optimize the footprint for wear. I think the footprints in the link below say that this test would have very similar results - or at least similar enough that the interpretation would be difficult.

Second, most tire wear occurs in the cornering mode, not driving straight ahead, so I think optimizing wear has more to do with alignment and driving conditions than inflation pressure. do not get me wrong: Inflation pressure is important - but for durability (non-failure) reason, not wear reasons.

The first thing hat occurred to me when looking at the footprints is the lack of contact at high pressure. It seems like that would increase the likelihood of losing grip on the road. But with a smaller footprint, fuel economy should increase. Given those competing qualities, it must be difficult for an auto manufacturer to recommend the “best” inflation pressure.

Those footprints tell me that, regardless of air pressure, modern steel-belted tires are remarkably good at keeping the tread pressure even across the tread.

Following my father’s advice, who was a tire engineer for over 35 years (I lost count), I always go by the higher (not necessarily highest) end of the manufacturer’s recommended pressure, especially on premium replacement tires.

The vehicle has a plaque on the door post that states the recommended tire pressure and it has nothing to do with how much the tire cost . On the side wall is a maximum psi meant for the tire mounting people , not what the tire should be inflated to for driving .

That usually reads something like Maximum load 1968 LBS @ 51 PSI cold.

There is sometimes a warning; Do not exceed 42 PSI while seating beads. I don’t think that could be confused with operating pressure.

Unfortunately it’s done all the time.

In a perfect world wouldn’t tire pressure be higher on the front wheels to account for engine and transmission weight?

Subaru specifies 2 psi higher pressure in the front tires of many of their models.

My 2012 Camry call for 35psi front and rear. I would say a Camry is a pretty mainstream car.

In a perfect world, the engine and transmission would be situated such that the weight would be almost even and this question would seem absurd! But we don’t live in that world.

In the world we do live in, tire rotation is important for max tire life - and in order to make that easier, many car manufacturers specify the same pressure front to rear, then adjust the springs, shocks, and sway bars to get the handling balance desired.

I used to let the front tires wear out then move the rears forward and put the new ones on back. For my 2017 Accord, I rotate when I change the oil, about 10,000 miles. Wear is even front and back and I have a ton of tread left after more than 48,000 miles.