Edmunds is wrapping up their 30,000 mile test of a Tesla S. During that time, they’ve had to have THREE drive units (which I think is the motor/rear axle assembly), and one main (large) battery replaced. All under warranty, of course, but WOW, that’s a lot of major problems in 30k miles.

http://www.edmunds.com/tesla/model-s/2013/long-term-road-test/2013-tesla-model-s-drive-unit-iv-the-milling.html

I just googled some things and the general feeling I get is that demand was so much higher than production ability that quality control was thrown out the window in order to meet orders. they seem to have consciously decided to deal with major warranty costs in order to meet demand.

if true, this is horrible production method and will ruin their reputation quickly, even if they fix everything later with a smile.

A sample of size one doesn’t prove anything. It will be interesting to see how the Tesla S holds up after five years and 100,000 miles of service in the hands of consumers. I am all for new technology as long as someone else tests its reliability. I don’t think I am quite ready to plunk down the cash for a Tesla. However, I am experimenting with the idea of an electric motor and rechargeable battery vs. an internal combustion engine. I bought a Black and Decker lawnmower from a friend who used it about a half a dozen times. This mower has an electric motor and a rechargeable battery. If the mower proves itself over time, I may consider a battery/electric car.

I was looking at the cordless mowers myself last spring. Unfortunately, my lawn is a little larger than the maximum that was recommended for them, so I went with a normal gas-powered one. I probably shouldn’t have gotten a Honda, because it will last until I’m dead or in a retirement home, so I’ll never get to try a cordless one after all

There are a number of people in my area who have Teslas now. The ones I’ve talked to are all very happy with their cars, and none have reported any big problems. They seem to have learned, at least, from their ridiculous mistake with the Roadster (draining the battery too much permanently bricked the car and required a 5-figure battery pack replacement because Tesla neglected to include a simple subroutine in the code that would kill power if the battery got too low). From what I’ve seen, when problems do crop up, Tesla fixes them quickly.

I don’t expect every car off a production line to be 100% flawless - as long as the company fixes it for free and without giving the owner a bunch of crap about it, I don’t think the occasional defect is really a problem.

“occasional defect”…this one car had the equivalent of three defective motors in 30,000 miles. I am aware of no extended test of any car that had that type of failure rate.

So much for the idea that electric cars have less maintenance…

Actually the experience Edmunds had with one car does reflect potential problems for the overall production. Their car failed one battery pack, which could well be an within the manufacturing reliability boundaries for a single car. This just means the battery packs should be better tested before leaving the supplier. Add to that a single drive motor and now Tesla should be concerned.

Add 2 failures more for a total of 3 drive motors tells us we have a design problem. Odds are that 3 failures across 10,000 cars would still give a reliability of 99.97%. 3 motors for the SAME car implies that virtually all the cars will have a motor replaced assuming worse case of it being a 3 sigma outlier on the bell curve. Not good for Tesla buyers!

But, one of the newer methods of research and development IS in fact to allow the warranty to be the test field. Recall if needed , redesign if warranted…or not.

I’ve seen it in Ford vehicles too.

Far too many in the shop under lower mileage warranty and we soon see a part number change which results in an obvious decline in shop repairs.

Just as engineers in the early 1800s were developing a new technology for propelling vehicles (the ICE), so is Tesla. It took generations, perhaps a century, for internal combustion engine drivetrains to become reliable. I’ll bet that the first Benz, in 1884, wasn’t all that reliable. It might be unrealistic to expect the first Teslas, using an entirely new energy storage system technology, to be as reliable as the average Corolla.

Personally, I think Tesla has made one heck of a good start. I applaud them. I wish I could afford to buy one and support them.

As of June 30, 2014, over 35,000 model S cars had been sold…They were turning out 600 cars a week…These are respectable numbers…

texases What about the Chevrolet Vega?

So much for the idea that electric cars have less maintenance.....

If they don’t take production shortcuts…then yes an electric car should/will have less maintenance. Less moving parts…means less maintenance.

Actually the experience Edmunds had with one car does reflect potential problems for the overall production.

Absolutely not. There isn’t a manufacture in the world who can produce 100% flawless vehicles…I’ll agree that the probability is low that they picked the ONE that had problems…but it’s not realistic to think that all will have the same problems.

@sgtrock21 - I don’t thing even a Vega would go through 3 engines in 30k.

And remember, this was 3 all new Tesla motor/axle assemblies that failed, not one that was repaired multiple times.

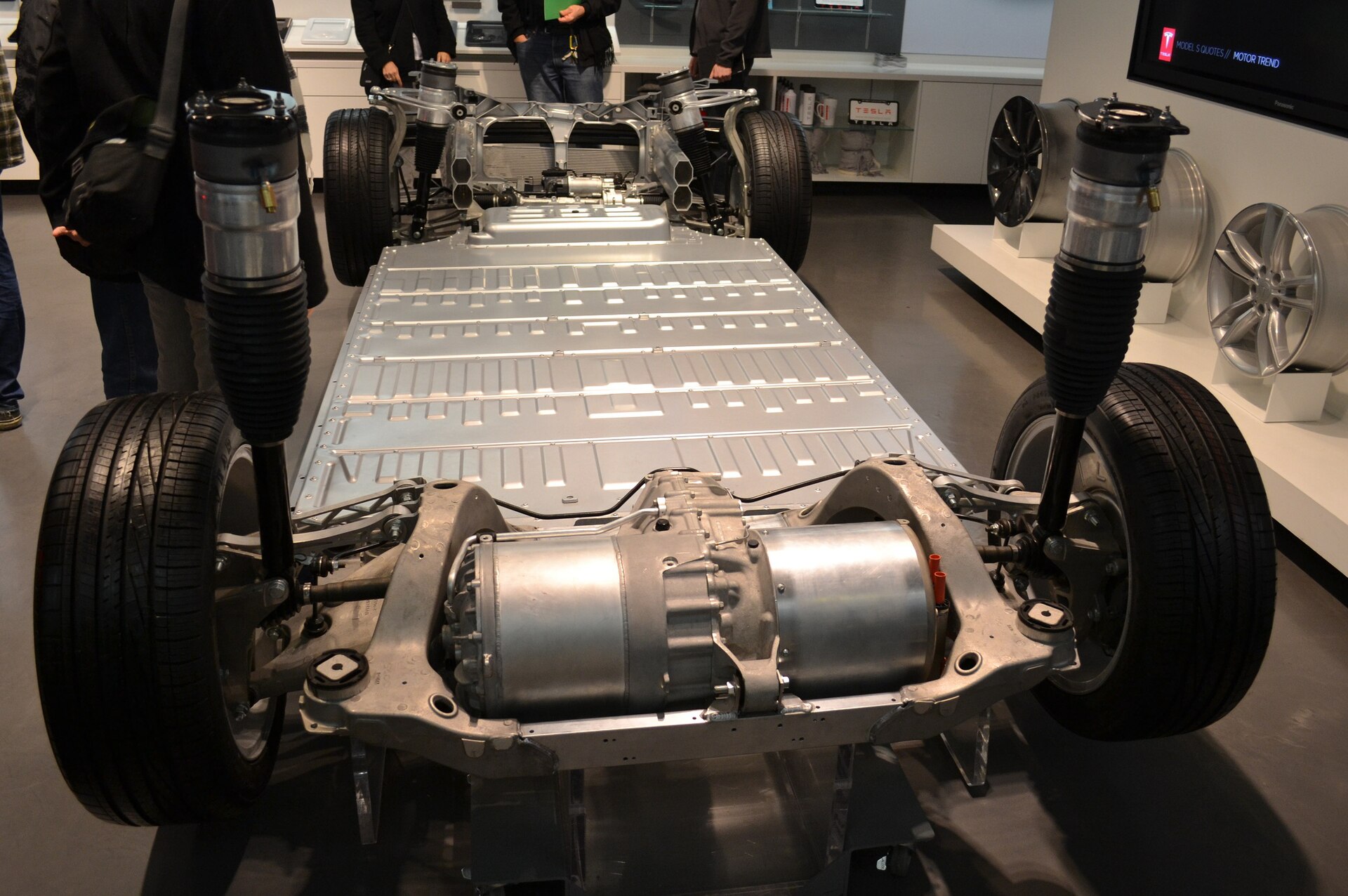

“During that time, they’ve had to have THREE drive units (which I think is the motor/rear axle assembly), and one main (large) battery replaced.”

Considering all the electric drive motors and trans. out there in Prius cars and other hybrids and full electrics including the Leaf with so many fewer problems in some of these related areas, it’s a statement about Teslar and not the viability of electric cars. It isn’t like electric motors have not been around for a while. Even specially designed units for the Teslar car should be trouble free. IMHO, I would fear buying from Teslar regardless of what kind of car they make if this is representative. It pretty much reinforces the idea too that car reliability is not always dependent on the price you pay for one.

This is similar to the reliability problems with CVTs we had discussed earlier. Crappy CVTs from crappy auto makers; reliable CVTs from reliable automakers. There are so many fewer moving parts in an electric motor drive assembly, it’s almost impossible to make one less reliable unless you set your own standards lower to begin with. I’m crossing Teslar off my list of cars for future purchase.

If one car by chance has this many problems in one test vehicle, it’s a huge red flag. That they coouldn’;t resolve the problem after the first failure is a huge red flag. IMHO, it is statistically valid. Don’t you thing that if a tested Corolla from CR in 30 k miles needed three motors and transmission replacements, CR wouldn’t red flag the Corolla in general and Toyota for being poorly prepared to sell and service the vehicle…bet you bootys !

Gee, when “big auto” teamed up with “big oil” to kill the electric car, because they’d “never break down” and make the “auto parts” supply line obsolete…perhaps they shouldn’t have sweated it!

I too applaud tesla and mr musk. altruistic is how I would describe him and I believe he truly wants to help humanity. tesla seems committed to improving their cars and not hiding their problems to avoid taking responsibility.

Edmunds may not be the most impartial judge either. they seem to take every opportunity to dump on tesla, almost gleefully, as do others

big oil and big auto had better get on board or china or india or germany will take the lead.

electric cars are here to stay and will only get better.

I hope mr musk brings us the next volkswagon beetle.

I say ,drill baby drill. but only to get us thru until we can replace these technologies in large part with cleaner and more efficient energy production.

depending on Arabia, Venezuela and Russia for energy is not good for the world

I believe this is exactly what they need…and probably want.

Some real life, kick-em-in-the-ass breakdowns to fully assess the problem potential.

@the same mountainbike Just as engineers in the early 1800s were developing a new technology for propelling vehicles (the ICE), so is Tesla. It took generations, perhaps a century, for internal combustion engine drivetrains to become reliable. I'll bet that the first Benz, in 1884, wasn't all that reliable. It might be unrealistic to expect the first Teslas, using an entirely new energy storage system technology, to be as reliable as the average Corolla.

Are you aware that electric motors go back just as far as internal combustion engines do? The assembly line that assembled Model T Fords was most likely powered by electric motors. I have personally seen electric motors as old as Model T Fords still in service even today.

Yup, I’m aware of that. But there’s no comparison between the energy storage and management systems in the 1800s and the systems Tesla has developed. They were about as much like the Tesla as the 1884 Benz is like the 2014 AMG Black.

texases I realize comparing engineering defects of a Vega which was (iron piston rings versus aluminum cylinders) internal combustion engine with a Tesla electric motor is apples and oranges. My example of the Vega is from personal experience. I rebuilt a Triumph TR4 transmission for a Nephew at cost which was $250. He paid $100 and had a problem paying the remaining $150. He had a 1971 Vega hatchback and offered it for the balance. I checked it out and accepted the offer. He purchased it from the original owner who had the original short block replaced under warranty at less than 11,000 miles. At about 18,000 miles the engine failed again. Under some obscure recall the original owner was given a new short block by GM with no $ for installation. The original owner had understandably lost all faith and sold the car to my Nephew for $500 with the brand new short block. His Mother was a State employee for corrections administration. The State prison had an automotive repair training program that was very popular with the prisoners. The short block was installed. The cylinder head was completely rebuilt, and the cooling system was flushed and filled for 0 $ He rarely drove the extra car. when I got the car, it had about 21,000 miles. of course the body, paint, and interior were like new. Never a problem with the 4 speed transmission clutch, or brakes. I enjoyed the Vega for about 18 Months. It was a fun drive and got good fuel mileage. At about 29,000 miles I was cruising on the Interstate at the 55mph limit. There was a pop followed by a puff of smoke from the exhaust. The rear wheels locked up! I pushed the clutch and shifted to neutral. I was very close to an exit and was able to coast to a parking lot. My Brother was able to tow me with his F100 1956 pickup. The next day I performed an autopsy. when I removed the cylinder head I discovered a 3/8ths by 3 inch piece of cylinder wall that had broken out and very successfully seized the engine. I had no faith and sold the car to someone who had a V8 Vega project in mind for $50. I can’t complain driving an almost new car for 18 Months for $100. I’m thinking in 1975 GM admitted the iron piston rings verses aluminum cylinder walls did not work and went with iron sleeves. Another Nephew bought a 1975 Vega wagon and drove it for 4 years with no problems. Of course by 1975 GM could hardly give Vegas away.

"Under some obscure recall the original owner was given a new short block by GM with no $ for installation."

That recall was by no means obscure. It was all over the news at the time.

You’re lucky the other major defect didn’t catch you by surprise… the retainers in the differential that held the axles into the bevel pinion gears used to fall out and the entire axle would slide right out of the housing. They issued a recall that involved checking the axle endplay. It was a total, complete, absolute coverup. I had mine checked twice under the recall, just to be sure, and the axle still came out. Fortunately, I was pulling into a gas station when it happened and barely rolling.