As a long-term Firestone employee, you might like this ad from 1943.

I wonder how much designing tires able to handle heavy aircraft landing at >100 mph helped in car tire development.

I don’t have a clue, Capri might know though, if any…

I did however had a plane maintenance company (when I worked at the closest airport shop) had a guy that paid the shop to properly dispose of airplane tires, they handled 2 sizes (don’t ask) of tires, the small one maybe 12-18" tall (20 years ago) had a max of 300 mph on it, and the much bigger one, close to waist high, had a 600 mph max speed on it, both sizes were very heavy for their size… Now I wish I would have weighed them… VERY thick rubber everywhere…

Even a small Cessna airplane is around 2000# loaded. The forces on the wheels have to be a lot when landing. The maximum a landing weight of a 777 is 425,000#. Even though there are a lot of those big tires, there is a huge shock load when landing. It’s not surprising that the tires are so robust.

Cool find with that 1943 Firestone ad. Makes sense that aircraft tire tech back then pushed car tire durability forward, especially with those insane landing speeds and loads. The replies about handling those massive, thick-rubber airplane tires (up to 600 mph rated) and comparing Cessna vs 777 weights drive home how brutal the engineering demands were. Good share for davesmopar, bet he’s got some stories from his Firestone days.

I had to look up the B-19.

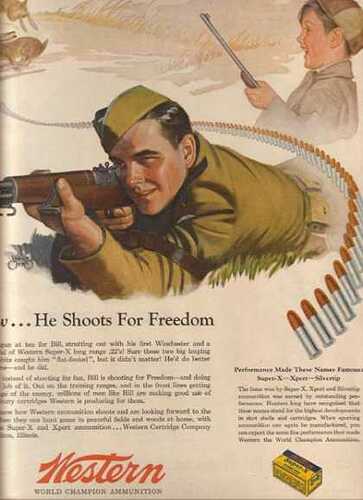

That advertisement was a little more subtle linking their product to the war, but many manufacturers did.

BTW, when I was first in, we still had C-rations, included a little four pack of cigarettes often Pall Malls or Chesterfields. With that blue pack, Newports or Salems?

Your basement should be designated as a recognized educational institution.

It was a Douglas prototype, never made service as a bomber.

But it looks like a lot of its design lineage went into their Globemaster airlift series.

The bomber image in your post looks like a Liberator.

Ford made them by the thousands (4600 or so), greater than one per hour at peak production.

Yes, B-24s were built at Ford’s Willow Run plant.

Wow, that is impressive!

The way this works is by selecting the size and inflation pressure, then testing to see if you need to tweak things. The size/inflation thing is set by a tire standardizing organization, like the US based Tire and Rim Association, based on fundamental research on what works and what doesn’t. These fundamentals are published in a book that gets issued every year. The average Joe can buy one, but they are pricey. All a guy needs to do is follow those standards and test.

Oh and the 600 mph thing? Take off and landing speeds are a lot lower than that. When an aircraft is going that fast, it isn’t using its tires.