Does your car have traction control? If so, are you able to turn off the traction control system? I’ve found that many times the trac control will do the job–that is, eliminate the chance of wheel spin–but to the detriment of of pleasant throttle response.

@ok4450: This isn’t a hiccup per se, in fact the car has always done this since new as did the test drive cars of almost every make and model. I started this thread mostly to find out why electronic throttle control tends to have that slight hesitation compared to what I was used to in previous cars and what the pros and cons are versus mechanical throttle control. Mind you, the Impala’s 6-cyls have good acceleration, better than parents’ 1983 Olds with its carburator 8-cyl engine. It just took getting used to the fractional hesitation. I just got to wondering about it.

The most rapid response engines I’ve ever driven have been the 1989 fuel injected 8-cyl Mercury Grand Marquis Dad had as a business car for a few years, the 3.8L 6-cyl in my 1987 Olds and, believe it or not, parents’ 1956 Olds with the V8 Rocket engine which actually surpassed the acceleration of the 1965 Olds with its bigger V8 engine.

Of course, from what I’ve learned over some years of reading here on the CT forum, there are multiple factors involved such as engine design, fuel injected or not, and how the transmission is geared, etc. I’ve wondered if the minor differences I noticed between GM vehicles’ throttle hesitation versus the Camry rental I drove a few months back are strictly a matter of the electronic throttle design or additional factors???

@asemaster: Yes, the car does have traction control which I leave on all the time. I never thought it might have anything to do with the slight hesitation. But considering it happens the most when going from standing still to rapid start, such as making a left turn from a “suicide turn lane” across busy traffic, perhaps the traction control does have some effect. Easy enough to turn it off with the flick of a button and see what difference it makes. I can easily turn it back on, especially in rain or other slick road conditions. I’ll give it a test try away from heavy traffic to get a feel for any difference in how the car responds. Thank you for the sugggestion.

See, still asking, still reading, still learning! I do so appreciate the education I get here from the kindness of many of you who take the time to answer questions for those of us who don’t know these things.

Marnet Duct Tape Specialist

June 12 @EllyEllis: There is a hill I drive almost every day with a 40 mph limit but traffic when heavy often goes about 35. When at that lower speed on the uphill the transmission spends a lot of time shifting up and down searching for where it wants to be. If I go a bit faster or slow down some it stops that.

I understand what you say here, but my peeve is people driving my car on level ground that keep pushing the gas and downshifting and then letting up and upshifting. Can’t they drive a steady speed? I was with my granddaughter tonight and on a long gravel hill she was going varoom, varoom, varoom, until she reached the top.

Yes, that is annoying. Also, driving behind someone who isn’t proficient at handling manual shifting.

I have noticed the the throttle is not what makes the difference for me, it is the shift points. My '05 Camry with the 5 speed auto hiccups when it drops from 1st to 2nd, esp if it is somewhere you need some torque. I either have to floor it, or listen to the cars behind me blow their horn.

I would have to admit that I prefer the more linear throttle response from my 1994 with a cable throttle than my 2006 with DBW. It seems almost like the 2006 tries to learn my driving habits and the throttle response changes depending on if I’m in a mellow or ‘spirited’ driving mood. So it either takes off too gently and shifts too soon, or I end up spinning the tires. I’d vastly prefer it to be the same every time, whatever that might be. I like modern tech, but I hate it when machines try to think for me, because they get it wrong every time.

I think one of the reasons for the “dampened” DBW response is to allow the O2 sensor to track the fuel/air ratio more accurately.

Control loops are challenged when conditions change too rapidly.

@galant - that era Camry was famous for hesitant shifting. I remember that problem when I rented one, always seems like I had to floor it to make it GO!

@oblivion: Computer controlled adaptive response is something else I hadn’t thought of. Given that my driving goes back and forth from fairly slow stop and go on surface streets to on and off the interstate loop at higher speeds in the metro area, I’m frequently changing from one extreme to the other in driving conditions. Perhaps I’m confoooozling the 'puter. That’s okay, cuz mechanical things easily confoooozle me!

@circuitsmith: If I understand you correctly, the DBW control fo fuel/air ratio is all about maximizing the mpg to meet CAFE requirements?

…still reading, still learning

@Marnet, one of the issues manufacturers have to deal with is a brief burst of hydrocarbon emissions when the driver of a manual transmission car shifts gears because the air/fuel ratio goes whacky for an instant.

It was a bigger problem in the '80s when computer controls were in their infancy and government regulations were getting ever tighter.

Some 5-speed models (vs 4-speed) were not sold in California because that extra shift pushed the HC emission over the limit on the drive cycle.

Multi-port fuel injection was a real game changer because the transient response is much better.

@circuitsmith: Does that hold true also for automatice transmission cars?

typo…should read automatic

It can be a factor with the auto trans too, but you get on and completely off the gas a lot more often shifting through the gears manually.

Related to this is a different problem - why speed bumps increase air pollution. Every time somebody slows down for a speed bump, they have to hit the gas to speed back up, creating an extra bit of air pollution. I seem to remember Great Britain trying to reduce the number of speed bumps in cities to reduce this.

Wow, I would never have thought speed bumps = air pollution.

Those of us who aren’t design engineers or the mechanics who maintain machinery likely haven’t a clue about more than a tiny fraction of what goes into making a complex machine such as a car work. Sometimes I look at the simplest tool around the house, such as a broom, and realize that the broom may be simple but the factory machines for mass production of said simple broom are likely far from simple. I’ve often wished I were far better at math because I would have been fascinated to study and become an engineer.

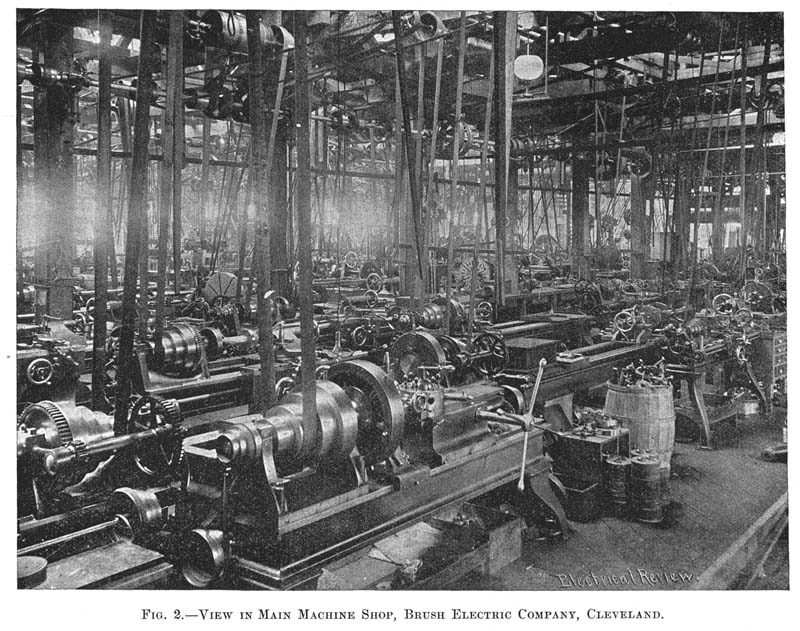

Back when I was a kid the Smithsonian Museum displayed factory machines from the late 1800’s and early 1900’s.

A whole building of machines powered by a big steam engine plus shafts and belts all over the place.

Ingenious.

Today the show “How’s It’s Made” shows things like potato chips or panty hose zipping by on a conveyer belt.

Even more impressive.

They don’t teach anything about how to design these things in most universities.

@circuitsmith–I really like the scenes inside the linen mill in the movie “Norma Rae”. There were belts and shafts all over the plant running the various pieces of equipment.

Oh yes, that particular building of the Smithsonian was so much fun to see the one time we went there almost 40 years ago. My dad had fun showing us the steam powered threshing machine like the one that would come around to farms at harvest time when he was a small boy and other such vintage items such as the steam roller, etc.

By the way, tried turning off the traction control and it makes no difference to throttle response, so I turned it back on again. It does come in handy now and then.

How come nobody has mentioned the idea that one reason that cars should have a drive by wire throttle is simplicity? I can’t think of a simpler way to do it and I’m both glad that the technology has arrived and frustrated that it’s still taking too long.

What could be simpler to operate and easier to maintain and repair than one throttle mechanism that used to take 3 or more mechanisms? Look at all the functions and components that can be eliminated by using one DBW throttle assembly.

No more throttle cable from the pedal through the firewall.

No more idle air control valve or similar device to control idle speed to compensate for engine load and to give a higher idle when cold.

No more separate cable and servo (vacuum or electric) to operate the cruise control.

No more electric intermediate motor and gears to activate throttle modulation as part of a traction control or stability system.

No more periodic adjustments to these systems as the cables wear and stretch.

Any lag in throttle response time is the result of programming and not the speed of the system. In my opinion anyway.