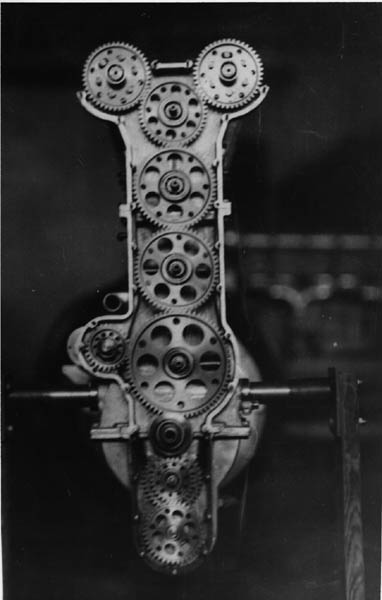

I agree; that Enzo setup is beautiful and only Lord knows how much money was spent just in engineering alone to come up with that.

Some may remember that back the mid/late 60s Chrysler spent 50 grand engineering the Roadrunner horn to go Beep-Beep. They probably could have done the same thing by using a 6 volt horn…

For what it’s worth, many SAABs used a gear drive with power fed from the crankshaft into the transmission mainshaft through a set of what is called primary gears.

Look at that picture and figure out what would be needed to run just one camshaft. And then tell me that a gear or gear/chain setup would have been more appropriate on a Pinto or Vega than a cheap timing belt which could be changed with simple hand tools on the side of the road.

I wonder how much a quart of Ferrari oil costs?

For what it’s worth, many SAABs used a gear drive with power fed from the crankshaft into the transmission mainshaft through a set of what is called primary gears.

I did like the feature of being able to replace a clutch without separating the engine from the transmission.

And I noticed that every gear that isn’t being turned by or turning a shaft is riding on ball bearings. That’s a really beautiful geartrain.

@asemaster Yes the design did make changing a clutch relatively simple. Separating the transmission from the engine was not so simple if the need ever arose.

Separating an automatic is even worse as the pan has to come off the transmission and there’s a rat’s nest of aluminum pressure tubes stuck into the valve body. All of the tubes have to be removed and put back into the right location.

The last Saab auto transmission I pulled was a 900 Turbo, the one where the trans housing also serves as the engine oil pan. The local trans shop we use sent their young parts driver to pick up the unit for overhaul. He looked at the unit on the floor and asked “Is that a transmission?”

It is Beautiful isnt it? A lot of math and machine work right there. But it ain’t new. I would have to look it up but I bet the first instance of this setup comes from the 30’s or 40’s… Hell it could even be before that.

When I stare at that gear drive setup I keep thinking how noisy it would be…in a cool way. I guess that’s just one part of the Concerto that this engine puts out when playing hard.

When did Saab use this and on what? Ive owned about 10-12 Saab 900’s and I grew to admire them. They were FUNKY but…still nice. Hated their transmissions tho…which SHARED their cases with the engine blocks… LOL… Oh Saab… LOL

Blackbird

In a Ferrari the sound of sirens behind you would muffle the sound of those timing gears.

Right, Honda BB, nothing new under the sun. This is a DOHC 4 valve 6 cylinder engine from 1920!

Read more about it here if you’re interested:

http://www.milleroffy.com/Junior%20Specials.htm

Harry Miller produced many stunning DOHC engines between WWI and WWII, including the basis for the long-lived “Offy” engine.

That link is quite interesting @texases. I can’t understand how the camshaft journals are aligned on 3 seperate heads though.

"I can’t understand how the camshaft journals are aligned on 3 separate heads though. "

Good question, RK. Since it was pretty much a one-off, maybe they spent a huge amount of time shimming the bases of the cylinders to get everything lined up.

Hmmm that statement just made me realize something. If there was ever an issue that required milling of a cylinder head that had gear driven cams…The clearances would be tightened up between the Valve train Gears! Probably too tight.

One of the advantages of a Chain and or a Belt…neither care if you mill off a “few thou” from the base of the Cylinder Head…the tensioner would take care of the difference on the slack side. But a gear drive certainly would care. On the engine with the Gear Drive it will either be remedied by a solid head gasket and plenty of clearance measurements…OR…or simply not allowed. Total Cyl Head replacement is the only way if you were to warp a head probably

I guess it just goes along with the Nose Bleed Price Range…Whats a new Head when you got the Greens to Burn?

Blackbird

Looks like the cams are running in a separate one-piece aluminum casting.

What would that have to do with the need to drive the cams that reside on the heads tho?

If you are responding to my comment Insightful…I think you lost me.

Anyway…no matter. I was just thinking out loud.

Blackbird

On engines like that the three cylinder blocks are separate from the crankcase, so one can shim them from the bottom to align them.

Mid 80’s GMs had chains with nylon gears. The gears stripped and the valves crashed. Replaced the gears and the chain on my 86 Siverado 5L.

I was responding to how the camshaft journals are aligned. They’re just bored through a single casting as is normal.

Edit: Each cam housing has an upper and lower half, not a “single casting”, per se.

Ah hah… I gotcha Thanks for clarifying.

The block holds the heads in alignment. The more famous “Offy” 4 cylinder engines had no removable heads, the valves had to be put in from the bottom before the pistons.